Diversification of biomass feedstock in Europe and in Brasil – Myrsini Christou, CRES

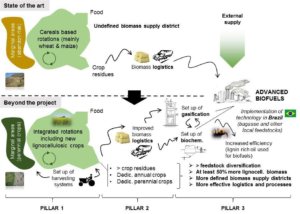

BECOOL tests and demonstrates integrated cropping systems based on dedicated annual lignocellulosic crops grown alongside conventional food crops, preferably in the periods of the year in which these are not cultivated. In this way, land competition between food and biofuel crops dramatically decreases, while land cover and use increase. Many environmental benefits will derive from implementing these integrated cropping systems, thanks to the positive interactions among different crops, such as rotational effects on the enhanced soil fertility, soil protection, landscaping, biodiversity, feedstock diversification etc.).

Innovative crop rotations and perennial grasses for advanced biofuels – Efthymia Alexopoulou, CRES

In addition to this, perennial grasses grown on marginal and idle lands will complement the lignocellulosic feedstock obtained from integrated ‘food-biofuel’ rotations.

Click to enlarge

Credit: Andrea Monti, University of Bologna

Efficient harvesting and mechanization for cost-competitive biomass – Luigi Pari, CREA

In addition, strategies for dealing with uncertainty of biomass supply and new logistic concepts will be developed. Currently, lignocellulosic biomass for advanced biofuels plants mostly consists of crop residues (such as cereal straw), whose availability for the industrial plant is uncertain and depends on many factors, such as the annual productivity of the crop in the radius of the supply area, and the demand for competing usages (animal bedding, mulching, soil amendment etc.).

GIS tools to optimize biomass logistic value chains – Bert Annevelink, Wageningen UR

In BECOOL, novel biomass logistic concepts will be applied to different conditions, in order to provide cost-effective logistic and to adapt the supply of biomass from a range of diverse feedstocks, to the requirements of standardized industrial conversion processes. This task will be based on the use of already available, effective logistic tools (ex. LocaGIStics, Bioloco and BeWhere), which will be further developed and applied to different conditions in the EU and Brazil, to elaborate innovative concepts such as biomass yards/hubs, intermediate collection points, different harvesting and transport systems, centralized and decentral pre-treatment steps etc.).

Developing efficient biomass delivery chains in Europe and in Brazil – Berien Elbersen, Wageningen UR

Keeping track and coordination between the European and the Brazilian projects – David Chiaramonti, RE-CORD

BECOOL aims at setting-up resilient thermochemical and biochemical conversion processes for advanced lignocellulosic biofuels, including biofuels for aviation. The feedstock can be either the whole biomass, as well as an intermediate energy carrier produced through fast, intermediate, or oxidative pyrolysis.

Gasification of different feedstock for conversion into biofuels – Berend Vreugdenhil, ECN

The use of intermediate energy carriers instead of raw biomass has two main advantages: first, it allows for accommodating case-specific logistics requirements, and second, it can improve the efficiency of the gasification itself. Compared to using raw biomass, the logistic constraints are less stringent as the increased energy density of the intermediate energy carrier allows for longer transportation distance and greater fuel economy. Moreover, the less complex composition of intermediate energy carriers, compared to raw biomass, increases the efficiency of gasification and the quality of the syngas.

Fast-pyrolysis oil gasification into advanced biofuels – Anja Oasmaa, VTT

BECOOL will also develop new fermentation and ethanol/lignin separation processes. In doing this, the project will evaluate the interactions among all the process steps (pre-treatment, hydrolysis, fermentation, and solid/liquid separation). In addition, integrated biochemical and thermochemical processes will be developed, to convert the lignin-rich residues of fermentation into additional biofuels. This will increase the resource and energy efficiency of advanced biofuels production process.

Lignin the interface between the biotechnology and the thermochemical platforms – Bert van de Beld, BTG

The sustainability of advanced biofuels will be assessed and quantified in terms of their impacts at environmental, socio-economic and biodiversity levels. BECOOL will develop a modular approach for the assessment of various value chains for the production of biofuels, based on information on feedstock potential, logistic chains, and processing technologies. An analysis of current and future market frameworks of those value chains will be also performed.

BECOOL will pursue a strategy for the exploitation of the project results in technology innovation, market acceptance and new business opportunities. In addition, the project will raise public awareness on the challenges, opportunities and environmental benefits of advanced biofuels in rotation with conventional crops. Several products and processes will be developed and validated in the industrial environment during the project, thus becoming potentially suitable for industrial exploitation. In addition to industries, the outcomes of the project activities will also benefit a wide spectrum of other potential end-users and adopters, ranging from research organizations, SMEs along the advanced biofuels value chain, as well as producer associations, advisory services, NGOs, policymakers, and the European citizens.