One research component of BECOOL aims at designing strategies to deal with the uncertainty of biomass supply and developing new logistic concepts for lignocellulosic biomass. Novel biomass logistic concepts will be applied to different conditions, in order to provide cost-effective logistic and to adapt the supply of biomass from a range of diverse feedstocks, to the requirements of standardized industrial conversion processes.

During the first year of activity, BECOOL partners have engaged in an intensive exchange of data and information, to clearly define the boundaries and the characteristics of the biomass value chains which are investigated by the project, and to match the data and the parameters deriving from cultivation and harvesting, with the feedstock requirements of the the conversion processes, in a harmonized way.

Assessing different biomass supply chains

The results of this work are described in the report BECOOL – Description of Full Biomass Supply Chains, completed in May 2018 and written by Wageningen University together with several other partners. The report provides a detailed description of the logistical concepts and of some exemplary chains for advanced lignocellulosic biofuels, produced from different feedstocks and under different regional conditions. A logistic chain is described as a specific transport route for biomass, from the field’s edge to the plant’s gate, encompassing transport, storage, handling and pre-treatment.

At this stage of the project, the logistic concepts consider all the different possible forms and systems for transport and pre-treatment of biomass (central, decentral, large and small-scale, long and short distances, by boat, train, lorry etc.). At a later stage of the project, a selection of the most suitable logistical concepts will be tested further for specific value chains and in specific regional case studies. As part of this work, the project will use an updated version of some already available logistical assessment tools, BeWhere, LocaGIStics and Bioloco, to evaluate the logistical chains made and presented in the report.

Schematic impression of a multi feedstock system with local sourcing of different types of biomass produced in the region (A) and point sourcing of imported biomass e.g. at a harbour (B). Source: BECOOL – Description of Full Biomass Supply Chains, figure 4.3.

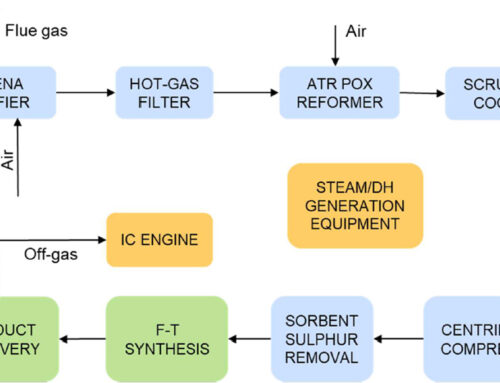

Eight types of logistical chains that can connect the biomass feedstock at roadside with the gate of the conversion plant are presented, which can include direct transport of biomass, intermediate collection points with biomass pre-treatment, multi-feedstock from local sourcing or local sourcing and point sourcing (harbour and or train station). Direct transportation is possible when sufficient biomass can be sourced from the local region at low cost. This can either work because the amount of biomass needed is relatively small and/or the spatial density of accessible biomass is high. Intermediate collection points are interesting to use if the biomass is located far from the conversion installation, orif it is more spatially dispersed over a larger region.

A new way to address the intermediate collection point within logistical chains

If there is a simple pre-treatment included in the intermediate collection point the biomass characteristics will change according to that pre-treatment. Pyrolysis can also be seen as a pre-treatment option as it changes the biomass into bio-oils, and these bio-oils will be further processed by gasification.

As a variation to a simple intermediate collection point, the more sophisticated biomass yard concept may be used. A biomass yard usually involves a more complex logistical handling with larger variations in pretreatments options of biomass and pre-treating many different types and origins of biomass at the same time. A biomass yard can be supplied by local, regional and long distance biomass of different types at the same time. And the biomass yard can supply one or more conversion installations in the wider local region or a more distant region, with a mix of feedstocks.

In a later stage, a selection of logistical chains presented in this report will be evaluated in a series of regional case studies, whose outcomes will be used for the integrated sustainability assessment of whole value chains. The logistical chains selected will also form the basis for the calculation of cost-supply curves for different combinations of biomass feedstock and conversion technologies.

Learn more about logistics in BECOOL from project partners Bert Annevelink and Berien Elbersen, Wageningen Research